· Imported the vertical grinding mill from Japan and Germany, can achieve the minimum economic batch, the highest machining accuracy and the interchangeability of bearing components.

· Complete all grinding with one clamping, achieve the minimum benchmark alignment, the minimum number of clamping, the minimum number of grinding, and maximize the use of high-speed grinding mill, 60m /s.

· The heat treatment equipment is world-class equipment (Aichelin), which can be used for carburizing, martensite and bainite quenching.

· It's all in accordance with human-machine engineering standards.

· Try our best to form production line, and the shortest component moving distance without detour transportation.

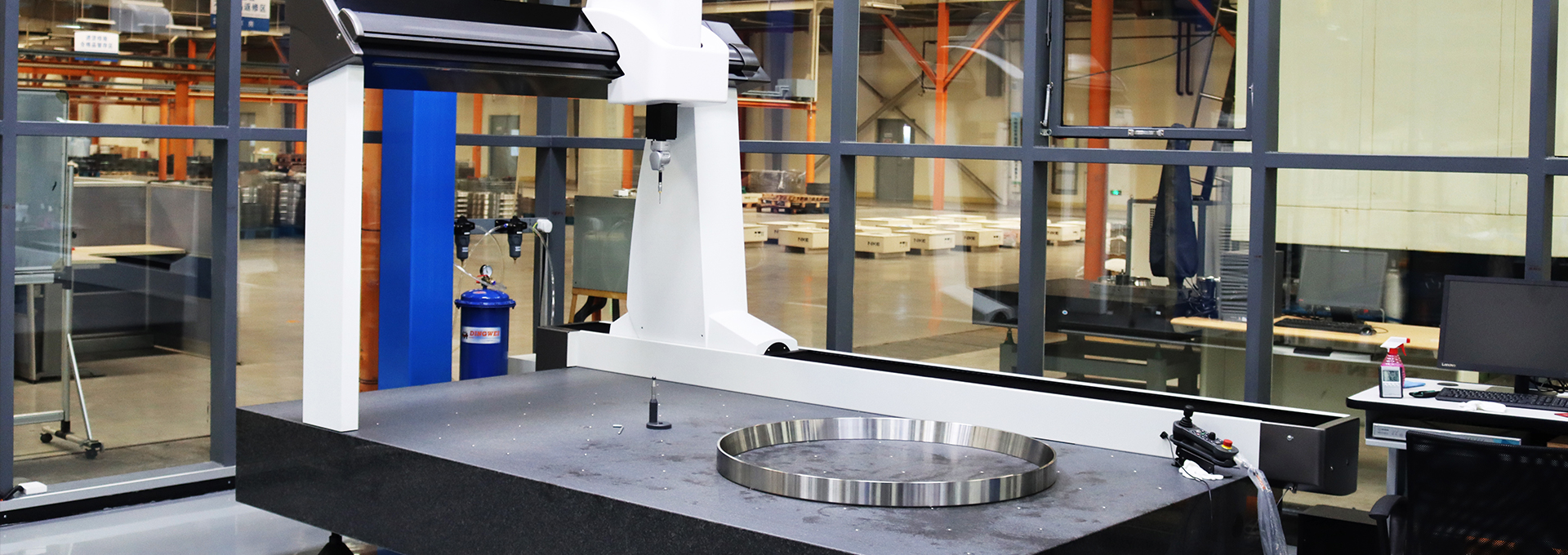

· Online data collection, online measurement, tool setting outside the machine, quick change of tooling, achieving fast, energy-saving, efficient and safe.

· Totally enclosed and air-conditioned workshop, each equipment is with oil mist dust collection device.

· Good capacity of spherical, cylindrical and tapered rollers, all of which are processed by ourselves.

· Consideration of security and efficiency factors, energy factors, we have variable frequency motor and energy-saving air conditioner. Realize the unification of energy saving, environmental protection and high efficiency.

· Delivery time and pricing advantages, overall cost performance ratio, more economical purchase cost + use and maintenance cost, maximize customer value.

Scan the QR code to read on your phone

Copyright © 2020, Shenyang Hanking Precision Bearing Co., Ltd. LIAO ICP BEI 20008201 HAO -1