We are committed to the development of large-size industrial precision bearings with independent intellectual property rights, which are mainly used in mining and Engineering Vibration machines, machine tool, primary metal, gear boxes, aerospace and other fields.

The goal is to manufacture large-size precision industrial bearings with the same engineering level as the international advanced bearing companies. Create the world's top bearing brands, and then compete with famous brand from Europe, America and Japan from technology and quality, replacing imported bearings.

· Turning, Grinding and Assembly

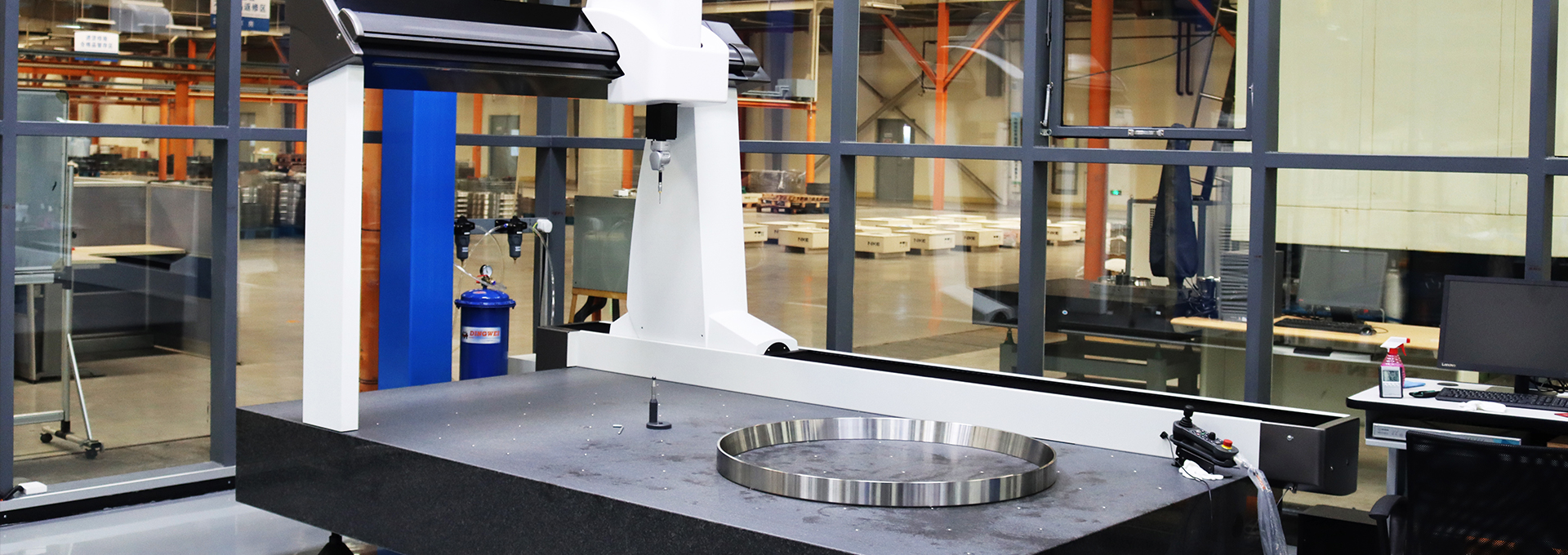

Imported from Japan and Germany as well as domestic vertical grinder, the maximum dimension is processed to 1400mm, flexible machining system with hard turning and face grinding, TRB,CRB,SRB collinear production can be realized.

Large size automatic washing line, can realize the maximum diameter of 1500mm ring demagnetization, washing, assembly.

SRB inner and outer ring grinding and super-finishing lines.

YOU JI Vertical lathe of oil machine (made in Taiwan) realizes hard turning of bearing ring, instead rough grinding with hard turning, improves grinding efficiency of ring.

|

|

|

|

Vertical Lathe · Taiwan You Ji |

Vertical Grinding-KEHREN |

Vertical Grinding-TAIYO KOKI |

· Rolling Element Manufacturing

We are making precision rollers, its processing accuracy can reach to class 0, and our positioning is high precision, high speed and long service life.

Special line for TRB / CRB roller grinding and super precision.

Spherical roller line (10-100mm) : 1.68 million Pcs / year

Cylindrical and tapered roller lines (10-100mm) : 1.38 million Pcs / year

· Heat Treatment

We have complete set of equipment of Austrian Aichelin Company, and each step is carefully designed to ensure the hardness (58hrc-63hrc), residual austenite (less than 10%), and residual stress of the material after quenching and tempering is in the reasonable range. Guarantees the mechanical properties of the material and the convenience of the subsequent processing. It strictly guarantees the metallurgical structure, roundness, warping and controllable tempering stability of the material after heat treatment.

|

|

|

|

Heat Treatment Workshop |

Case Harden |

Case Harden Furnace |

Scan the QR code to read on your phone

Copyright © 2020, Shenyang Hanking Precision Bearing Co., Ltd. LIAO ICP BEI 20008201 HAO -1